– Pursues carbon neutrality by 2045

Lagos — Tata Steel Ltd and global technology leader ABB have signed a Memorandum of Understanding (MoU) and will work together to co-create innovative models and technologies to help reduce the carbon footprint of steel production. ABB will bring global experience in automation, electrification and digitalization for the mining and metals industries.

Tata Steel is among the top global steel companies with a crude steel capacity of 35 million tons per annum and is committed to major sustainability targets including achievement of carbon neutrality by 2045.

In line with its aspirations, the steelmaker has a medium-term target to reduce carbon emissions to less than two tons of CO₂ per ton of crude steel in its Indian operations by 2025.

The two companies will focus on system-level assessments of Tata Steel’s manufacturing plants and production facilities for evaluation and co-development of short and long-term options for energy efficiency, decarbonization and circularity.

“Steel companies know there are opportunities to improve their processes, and Tata Steel is one of the leaders in this movement towards energy efficiency and reduction of carbon footprint,” said Vipul Gautam, Group Vice President, Global Account Executive for Tata Group, ABB.

“World Economic Forum figures anticipate the energy transition will require as much as three billion tons of metals over the medium term; six times more mineral inputs by 2040 to reach net-zero emissions globally by 2050. ABB is confident in working with our customers and partners to evolve how steelmaking is powered to help reach production and environmental targets.”

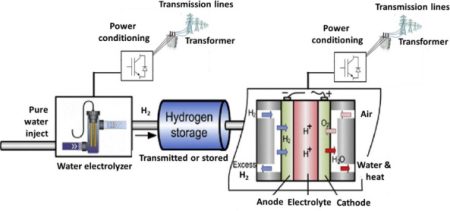

Tata Steel is committed to sustainable development and growth as an integral part of its business philosophy. To ensure sustainable growth, the company is working on deployment of key enablers for deep decarbonization, including the use of more scrap in steelmaking, use of alternate fuels such as natural gas and green hydrogen, use of renewable energy and deployment of carbon capture and storage/utilization technologies. Tata Steel expects to increase capacity to 40 million tons by 2030 hence this collaboration with technology partner ABB is a key enabler to achieve that growth in a sustainable manner.

ABB and Tata Steel will explore energy optimization via hydrogen as an alternative fuel for upstream processes and energy reduction as well as substitution through fully integrated electrification and digital systems such as ABB Ability™ eMine and e-Mobility solutions and energy efficient motors.

The global steel industry contributes between 7 to 9 percent of global fossil fuel CO₂ emissions, according to various sources including the International Energy Agency (IEA).

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.