08 January 2018, Sweetcrude, Lagos — Wind power has become an important source of energy over the past few decades as emphasis is being shifted from fossil fuels to renewable energy. Larger, more efficient turbine designs have produced ever-increasing amounts of power. The first wind turbine used to convert wind energy into power was built by Professor James Blyth of Anderson’s College, Glasgow (now Strathclyde University) in 1887. Blyth’s experiments with three different turbine designs resulted in a 10-meter-high (33-foot-high), cloth-sailed wind turbine, which was installed in the garden of his holiday cottage at Marykirk in Kincardineshire. It is said to have operated for 25 years. Blyth’s invention marked the dawn of wind turbine development. Close on its heels was a turbine built by American inventor Charles Brush in 1888. That 12-kW turbine featured 144 blades made of cedar, each with a rotating diameter of 17 meters.

Today, most modern wind turbine designs continue to be classified according to the configuration of the rotating axis of their rotor blades. Two categories dominate horizontal-axis wind turbines (HAWTs) and vertical-axis wind turbines (VAWTs). More than 90% of wind turbines in use today are thought to be of HAWT design. HAWTs dominate the market is that the arrangement of their blades allows them to always fully interact with the wind, which critically improves the power coefficient of modern HAWT turbines. HAWTs are also technically limited in three critical ways. HAWTs are unable to withstand turbulent winds found in urban environments as well as cannot operate in high winds because large turbines must yaw (or turn) their blades out of the wind and apply a brake when wind speeds reach about 55 miles per hour (mph)

Problems with wind turbines

Wind turbines have some negative impact on the environment. A common disadvantage with wind turbines is that they are noisy. Broadband noise, mainly originating from aerodynamic phenomena (like airflow around the blades, hub, and tower), and tonal noise, caused by the vibration of mechanical components, can range in sound pressure levels ranging from 58 dBA (just above ambient noise) to 108 dBA. Wind farms take up a bit of space and this obviously results in some habitat destruction. Another problem with wind turbines involves increases in mortality rate in relation to certain bird species. Depending on where they are placed, wind turbines may increase wildlife fatalities. However, the impact that these structures have does greatly depend on where they are placed. For example, in Altamont Pass in California, some 1,300 birds of prey are killed each year by rotating wind turbine blades. Also one of the biggest criticisms against wind turbines farm is that they aren’t usually nice to look at and does not add to the scenic view of an environment.

Challenges with wind turbines

Transportation of wind turbines is increasingly challenging because of the size of the components: individual blades and tower sections often require specialized trucks and straight, wide roads. Today’s wind turbines are also incredibly top heavy. Generators and gearboxes sitting on support towers 100 meters off the ground can weigh more than 100 tons. As the weight and height of turbines increase, the materials costs of wider, stronger support towers, as well as the cost of maintaining components housed so far from the ground, are cutting into the efficiency benefits of larger turbines.

The alternative energy industry has repeatedly tried to solve these issues to no avail. But the latest entry promises a radically different type of wind turbine: a bladeless cylinder that oscillates or vibrates.

Spanish startup Vortex Bladeless has developed turbines that harness vorticity, the spinning motion of air or other fluids. When wind passes one of the cylindrical turbines, it shears off the downwind side of the cylinder in a spinning whirlpool or vortex. That vortex then exerts force on the cylinder, causing it to vibrate. The kinetic energy of the oscillating cylinder is converted to electricity through a linear generator similar to those used to harness wave energy. Vortex’s lightweight cylinder design has no gears or bearings. it will generate electricity for 40 percent less than the cost of power from conventional wind turbines.

Their idea is the Vortex, a bladeless wind turbine that looks like a giant rolled joint shooting into the sky. The Vortex has the same goals as conventional wind turbines: To turn breezes into kinetic energy that can be used as electricity. But it goes about it in an entirely different way.

Instead of capturing energy via the circular motion of a propeller, the Vortex takes advantage of what’s known as vorticity, an aerodynamic effect that produces a pattern of spinning vortices. Vorticity has long been considered the enemy of architects and engineers, who actively try to design their way around these whirlpools of wind. And for good reason: With enough wind, vorticity can lead to an oscillating motion in structures, which, in some cases, like the Tacoma Narrows Bridge, can cause their eventual collapse.

Where designers see the danger, Vortex Bladeless’s founders—David Suriol, David Yáñez, and Raul Martín—sees opportunity. “We said, ‘Why don’t we try to use this energy, not avoid it,’” Suriol says. The team started Vortex Bladeless in 2010 as a way to turn this vibrating energy into something productive. They just launched a crowdfunding campaign to raise awareness of the technology.

The Vortex’s shape was developed computationally to ensure the spinning wind (vortices) occurs synchronously along the entirety of the mast. “The swirls have to work together to achieve good performance,” Villarreal explains. In its current prototype, the elongated cone is made from a composite of fiberglass and carbon fiber, which allows the mast to vibrate as much as possible (an increase in mass reduces natural frequency). At the base of the cone are two rings of repelling magnets, which act as a sort of nonelectrical motor. When the cone oscillates one way, the repelling magnets pull it in the other direction, like a slight nudge to boost the mast’s movement regardless of wind speed. This kinetic energy is then converted into electricity via an alternator that multiplies the frequency of the mast’s oscillation to improve the energy-gathering efficiency.

Its makers boast the fact that there are no gears, bolts, or mechanically moving parts, which they say makes the Vortex cheaper to manufacture and maintain. The founders claim their Vortex Mini, which stands at around 41 feet tall, can capture up to 40 percent of the wind’s power during ideal conditions (this is when the wind is blowing at around 26 miles per hour). Based on field testing, the Mini ultimately captures 30 percent less than conventional wind turbines, but that shortcoming is compensated by the fact that you can put double the Vortex turbines into the same space as a propeller turbine.

The Vortex team says there are some clear advantages to their model: It’s less expensive to manufacture, totally silent, and safer for birds since there are no blades to fly into. Vortex Bladeless says its turbine would cost around 51 percent less than a traditional turbine whose major costs come from the blades and support system. Plus, Suriol says, it’s pretty cool-looking. “It looks like asparagus,” he says. “It’s much more natural.”

A conventional wind turbine typically converts 80 to 90 percent of the kinetic energy of its spinning rotor into electricity. Vortex Bladeless has a custom-built linear generator that will have a conversion efficiency of 70 percent. Vortex Bladeless oscillating turbine design will sweep a smaller area and have a lower conversion efficiency, but says significant reductions in manufacturing and maintenance costs will outweigh the losses.

As Vortex builds bigger devices that catch higher-speed winds further from the ground, it will also run up against other challenges inherent to the physics of fluid mechanics. Air or other fluids moving at low speeds past small-diameter cylinders flow in a smooth, constant motion. Increase the diameter of the cylinder and the speed at which the air flows across it, however, and the flow becomes turbulent, producing chaotic eddies or vortices. The turbulent flow causes the oscillating frequency of the cylinder to vary, making it difficult to optimize for energy production.

Other Innovations

Oscillating cylinders are just one of several emerging technologies aimed at harvesting more of the wind for less. While most wind energy projects are firmly rooted in the ground or at sea, some recent innovations are putting turbines high in the sky, where wind moves fastest. The world’s first airborne wind turbine launched in 2014 over Fairbanks, Alaska. Held aloft by helium like a giant cylindrical blimp, the BAT-Buoyant Airborne Turbine was designed and built by MIT startup Altaeros Energies to float 1,000 feet in the air and capture wind currents five to eight times more powerful than the breezes at ground level. The 18-month experiment generated enough energy to power a dozen households. Because of their sky-high positioning, BAT systems can also transmit WiFi and cell signals, and double as weather sensors.

NewWind’s, Tree Vent

French company NewWind is developing a new ecstatic device, the tree vent turbine. Tree Vent is an array of vertical wind turbines that look a lot like a tree. Though the tree looks like a piece of modern art that would fit in at any urban area, it also provides a very important function. Each tree has a current power output of 3.1 kilowatts, which might not be able to power much on its own. However, using several of the trees together as landscape features in a park or along a roadside would make more of an impact to the homes and buildings nearby.

The trees are 11 meters (36 ft) tall, and 8 meters (26 ft) in diameter at its widest point, which makes it about the same height as many urban trees. The white frame of the tree is made out of steel, and it can hold 72 turbines that sit vertically. This orientation cancels out noise, allowing the turbine to spin silently. Wind turbines are typically very tall in order to reach the altitude where the wind is stronger, but these vertical turbines are able to spin with the wind blowing as low as 7 km/h (4.4 mph), making this twice as sensitive as traditional turbines. However, they are durable enough to withstand Category 3 winds, which can reach 178 – 208 km/h (111-129 mph).

Each turbine “sheet,” called an Aeroleaf, is constructed out of lightweight plastic. The plastic has been treated with a resin which protects it from weather conditions such as humidity and salt (for areas close to the sea). The turbines are wired in parallel so that if one stops working for whatever reason, the others will not be affected.

Typhoon Turbine

The world’s first typhoon turbine was invented by Atsushi Shimizu to tap into the massive amounts of energy contained within storms common to his homeland of Japan. He estimates the energy stored in one typhoon could power the nation for 50 years, if only it could be harnessed. Shimizu’s egg beater-like contraption is a vertical-axis Magnus wind power generator robust enough to withstand the high winds of a typhoon. Tests conducted using a scale model of the wind energy generator have been promising, and Shimizu is on a mission to connect with investors to help build larger practical versions in the hopes of one-day feeding typhoon power into the nation’s grid.

Zero-Blade technology vy Saphon of Tunisia

When it comes to the future of wind power, one company thinks it looks a lot different than you would expect and cheaper and more efficient to boot. Saphon, out of Tunisia, is interested in finding partners to mass-produce and market their unique wind energy device, baZero-Bladeir own Zero-Blade technology, “The Zero-Blade Technology is largely inspired from the sailboat and is likely to increase the efficiency of the current wind power conversion devices. The blades are replaced by a sail shaped body while both hub and gearbox are removed.”

According to the company, their zero-blade technology devices are capable of overcoming the Betz’ limit, which states that no turbine can capture more than 59.3 percent of the kinetic energy of the wind. An average wind turbine captures only 30 to 40%, while the Saphon turbine is said to be 2.3 times more efficient. Additionally, the cost is expected to be 45% less than a conventional turbine, mostly due to the fact that there are no blades, no hub, and no gearbox on the units. The Saphon Zero-Blade technology is different in other ways as well, most significantly being storage of energy. Most of the kinetic energy can be stored (via a hydraulic accumulator) or converted to electricity with a hydraulic motor and generator.

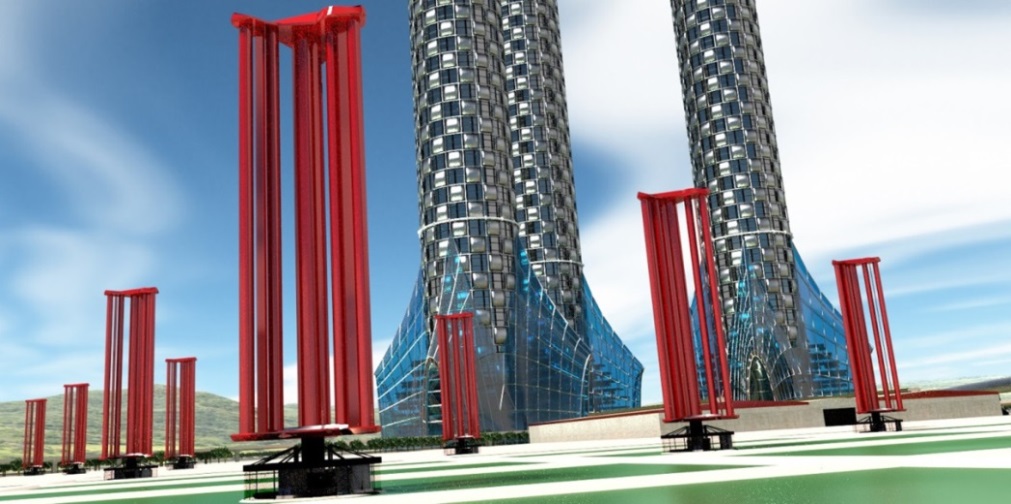

INVELOX wind tunnel tower

This innovative wind turbine is capable of producing 600 times more energy than conventional windmills. The SheerWind Invelox turbine is a tunnel-based wind energy generator that harnesses breezes at ground level and funnels them inward, accelerating the air’s speed. The Invelox generator can function even in low-wind conditions and, since it has no external blades rotating at high speeds, it doesn’t endanger local wildlife. It’s also less expensive to build than traditional wind turbines.